Compared to other air-sampling systems that detect fire in ‘clean rooms’, the A4S was especially developed to also function in a very dirty and dusty environment.

- Combines analogue point detector and air-sampling detector

- Utmost sensitive fire detection

- Simple cabling

- Suction through a thin flexible hose

- Deployable in both clean and very dusty environments

- Filters are easily replaceable by means of a cassette system

The detector combines the advantages of an analogue point-detector with those of an air-sampling detector:

- Sensitive fire detection, even when the airflow is low.

- Simple cabling, no piping system: suction through a thin (Ø 6mm) flexible hose.

- Full identifcation and measurement data per suction point.

The detection is individual: There is a single suction point per A4S. Via the bi-directional fire detection loop, all the measurements and parameters are transmitted to the fire detection control unit. It is possible to connect 25 A4S detectors to a single bi-directional fire detection loop.

Each A4S contains an optical fire detection sensor.

In option:

- Temperature and rising temperature at the suction mouth as an option

- Multi-sensor measurement values (optical detector with increased sensitivity in case of temperature rise)

- CO detection as an option

The measured values from all these sensors can be retrieved from the fire alarm control unit.

The alarm levels can be adjusted from the fire alarm control unit per sensor type and per A4S.

Each A4S contains extensive operational checks:

- Measuring underpressure: In order to immediately report any blockage or leaks in the suction system.

- Measuring suction capacity: To be able to check the suction system and the suction filter.

- Measuring the filter bore: So that the filters are not replaced too soon nor too late.

- Measuring pump amplitude: A check of the suction system.

- Measuring the power supply voltage and current in the suction system: To be able to check the power supply remotely.

The A4S is built as an internal modular model. The filters can be changed manually: They slide into and out of a collector block. Maintenance is therefore simple.

Maintenance

The design of the filters allow you to carry out maintenance service only once per year. However, the actual maintenance will depend on the specific environment.

If necessary, the modules can be easily and quickly replaced on the spot. Since the fire alarm control unit receives all the measurements of the operational parameters continuously, the maintenance software can provide detailed warnings.

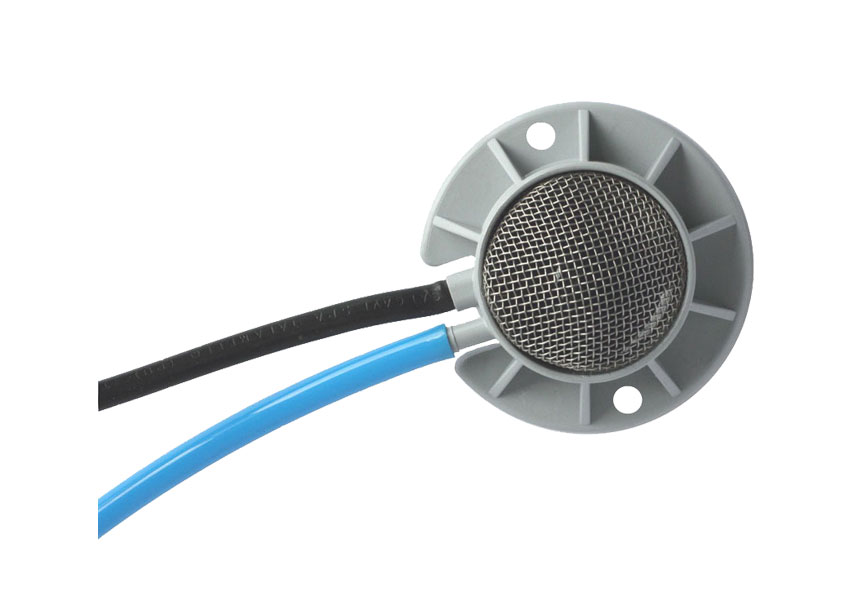

The suction point is designed as a suction mouth: The relative small circle-like suction mouth has a diameter of 60 mm. Its form makes it very sturdy. The stainless steel mesh cupola prevents blockage from flying dirt. There is a nipple for connecting the flexible hose. The cast temperature sensor is connected with a cable attached by casting. There are two fixing holes with 5mm diameter at a centre distance of 50mm.

Suction hose

The hose is Festo brand, type PU-4-BL (part number 6204); external diameter is 6mm, internal diameter is 4mm. The suction hose can be between 0 and 20m long. The suction hose usually slides into a tube (minimum 5/8”) together with the cable for the temperature sensor.

Minimum tube radius: 8cm

Suction detector

Connections with the suction mouth:

- Equipped with a fast connection to the flexible hose of the suction mouth

- The cable of the temperature sensor is attached to the connector in the detector.

Other connections

- Connection on a bi-directional fire detection loop: 2-polar. Two sets for the sake of simplicity: two clamps for the incoming loop (E+/E-) and two clamps for the outgoing loop (0+/0-).

- Connection to the power supply voltage 24VDC: 2-polar. Two sets for the sake of simplicity: two clamps for the incoming power supply voltage (P+/P-) and two clamps for the outgoing power supply voltage (P+/P-).

- Power supply voltage: 24VDC nominal (18Vmin..29Vmax)

- Current consumption: Max. 100mA

- On power supply: (75mA/18V 50mA/29V)

- Data interface: Bi-directional fire detection loop, communication is maintained in case of failures of the external power supply voltage.

- Current on loop: Typical 4.5mA

- Short-circuited insulator on loop: 1 per A4S, integrated

- Number of A4S on a single loop: Maximum 25

- Operating temperature: -10º…+50ºC

- Humidity

- 0…95%

- no condensation

- Detection principle

- Optical, thermal

- CO-gas is optional.

- Detection element: Bosec certified IOT detector

- IP rating A4S: IP53

- Material of housing: PC, halogen-free

- Protected parameters

- Under-pressure suction hose

- Flow suction system

- Filter bore

- Amplitude pump

- Power supply voltage/current of the suction system

- Maximum suction length: 20 meters

- Diameter of suction hose

- 3.9 mm internally

- 6.1 mm externally

- Detector dimensions: 215W x 300H x 185D (excluding mounting feet)

- Dimensions of suction mouth: 60mm diam. x 30mm height

- Mounting: 2 bore holes 5mm diam. at a centre distance of 50mm

- Suction hose

- Festo PU-4-BL

- part no. 6204

- Maximum bend radius of the hose: 8 cm

- Mounting the A4S: Mount the housing vertically (deviation of max. 10°)

- Cable supply

- 3 swivels PG13.5 (2x loop & 1x supply)

- 1 swivel PG7 (thermal suction mouth)